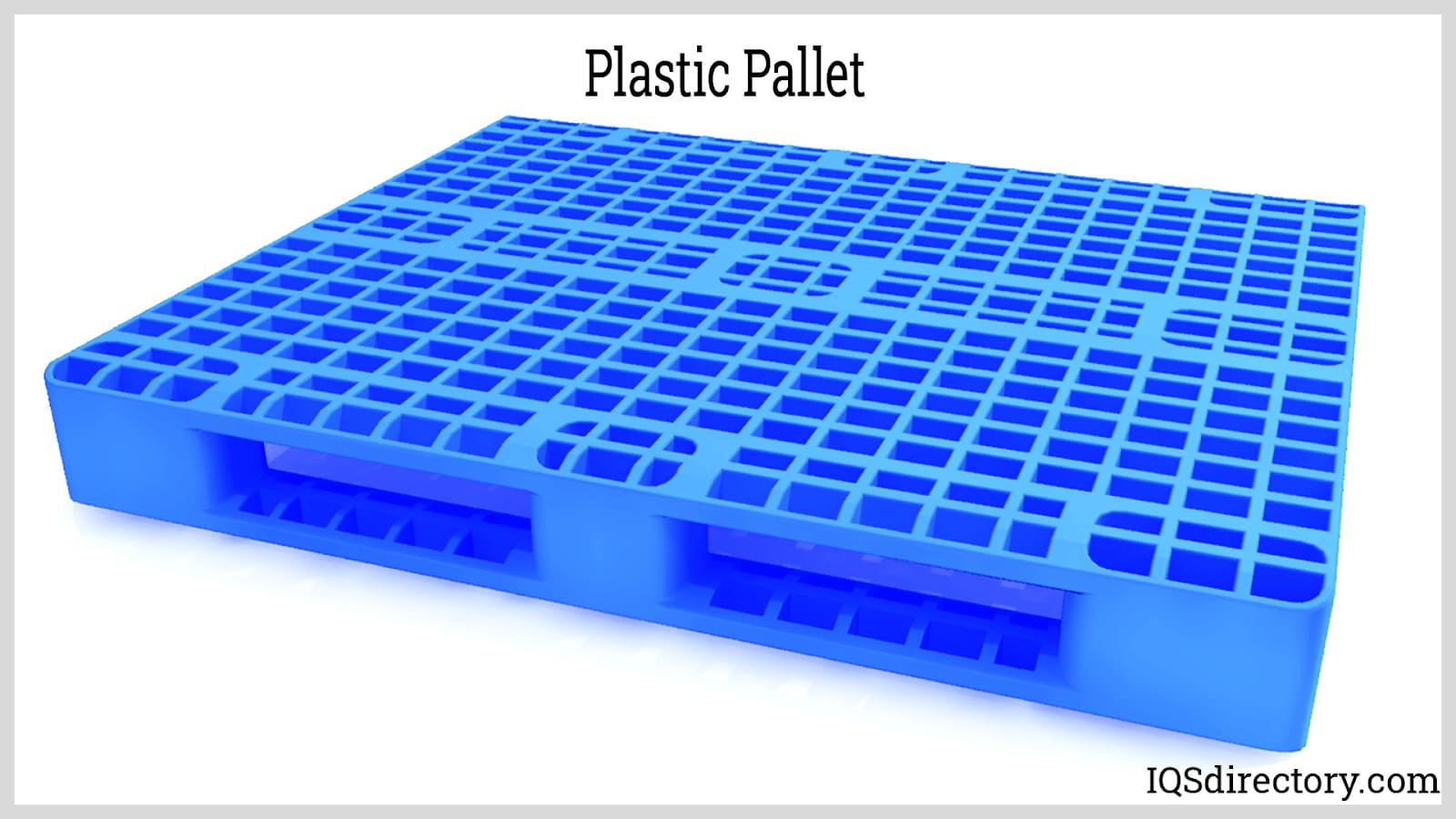

Recycled pallets refer to flat transport structures made from recycled plastic materials. They are used to support goods stably as they are carried from one point to another using a forklift, pallet jack, front loader, jacking device, or crane. Recycled pallets are usually made of strong plastic or wooden material that can withstand very strong weights without faulting. Read More…

TMF Corporation manufactures and supplies the Protech 4048 heavy duty plastic pallet. With inventory on hand, we have the ability quickly deliver and pallets we have in stock, including the FM approved Protech 4048 with color options, four-way entry and more.

At Premier Handling Solutions, we provide warehouse equipment solutions that improve overall productivity, safety and speed throughout the manufacturing, warehousing, distribution, consumption, storage and disposal process. Browse our selection of pallets, inverters, tippers, wire containers, and pallet dispensers to find the perfect product for your application.

At Peninsula Plastics, you can find high-performance, vacuum-formed reusable plastic pallets for maximum strength and durability. Our economical twin-sheet & single-sheet pallets feature nestable and stackable models, large load capacity, many sizes, guaranteed acceptance at all ports, use in demanding applications, and with automated systems.

At Craemer US Corporation, we specialize in providing comprehensive solutions for plastic pallets tailored to meet the diverse needs of our clientele. With decades of experience and a commitment to excellence in the plastics industry, we have established ourselves as a trusted leader in plastic pallet manufacturing, renowned for our dedication to quality, innovation, and customer satisfaction....

Robinson Industries reduces operational costs and worker injuries through providing superior-quality plastic pallets. We sell pallets in a variety of sizes and styles. Robinson Industries is ready and able to meet diverse industry needs.

Fibertech Plastic pallets are an excellent alternative to wood pallets, offering cost-efficient solutions for strong, durable & washable pallets. Our unique angled leg design helps reduce forklift damage by enabling the fork tines to deflect off the leg rather than breaking or cutting the pallet. An optional lip prevents product slippage & facilitates transportation of stacked, empty pallets.

More Recycled Pallet Manufacturers

How Recycled Pallets Function

Recycled pallets are usually made of strong plastic or wooden material that can withstand strong weights without faulting. Some goods require fastening, so a strong rope is used to secure them and ensure they will not tumble off the pallet. The pallet is lifted from either side by a forklift that inserts extended blades through the openings at the pallet's base.

Other mechanisms can also be used, like a pallet jack that acts as a manual handheld wheelbarrow to carry pallets from one point to the other.

How Recycled Pallets are Made

Plastic is brought to a recycling center, where it is cleaned and passed through a plastic shredder that cuts it down into small pieces and granules. The plastic is then heated and molded into the desired pallet shape and size. After cooling, the pallet is branded and de-flashed for commercial and industrial use.

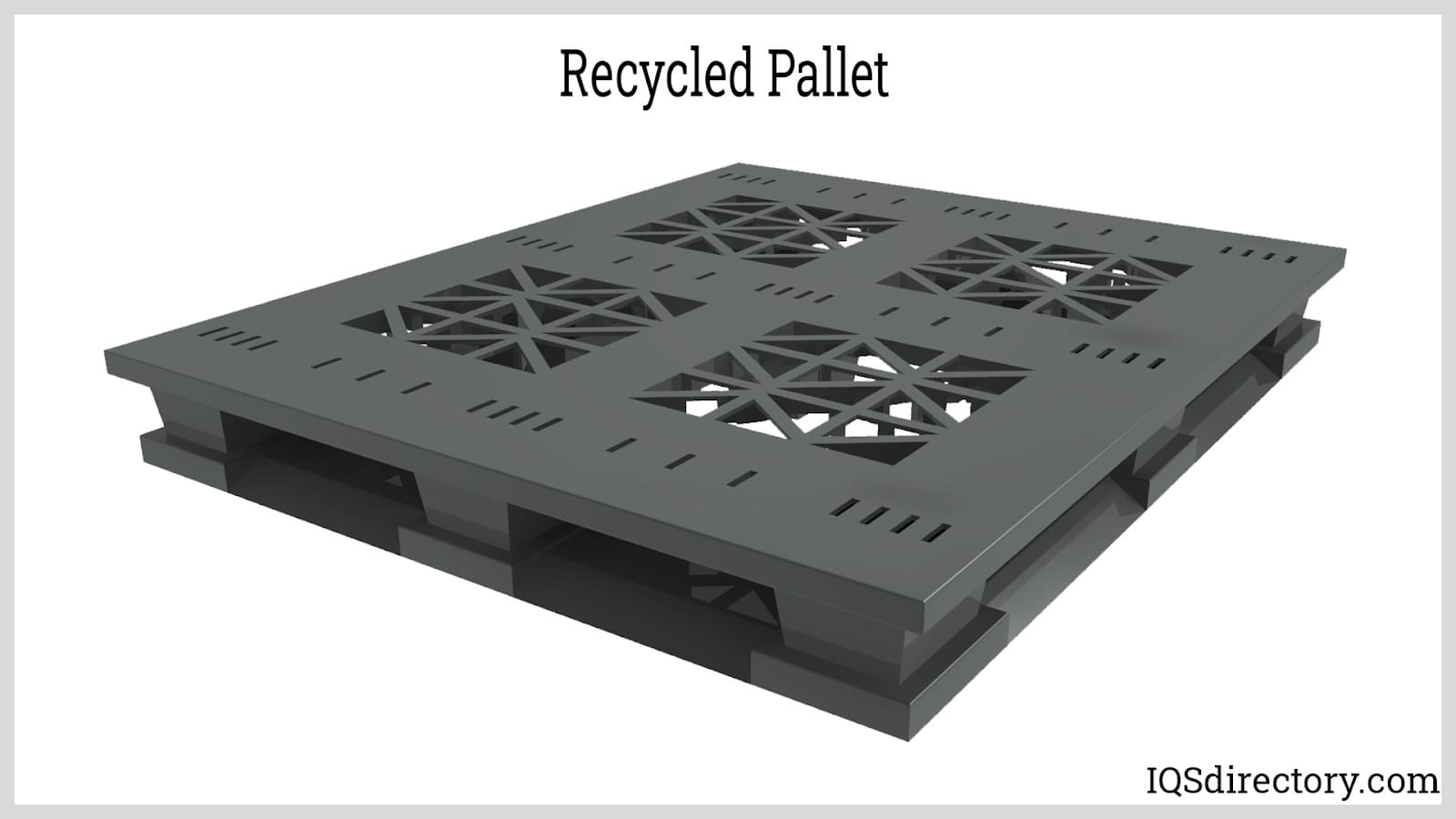

Types of Recycled Pallets

The different types of pallets that can be recycled include:

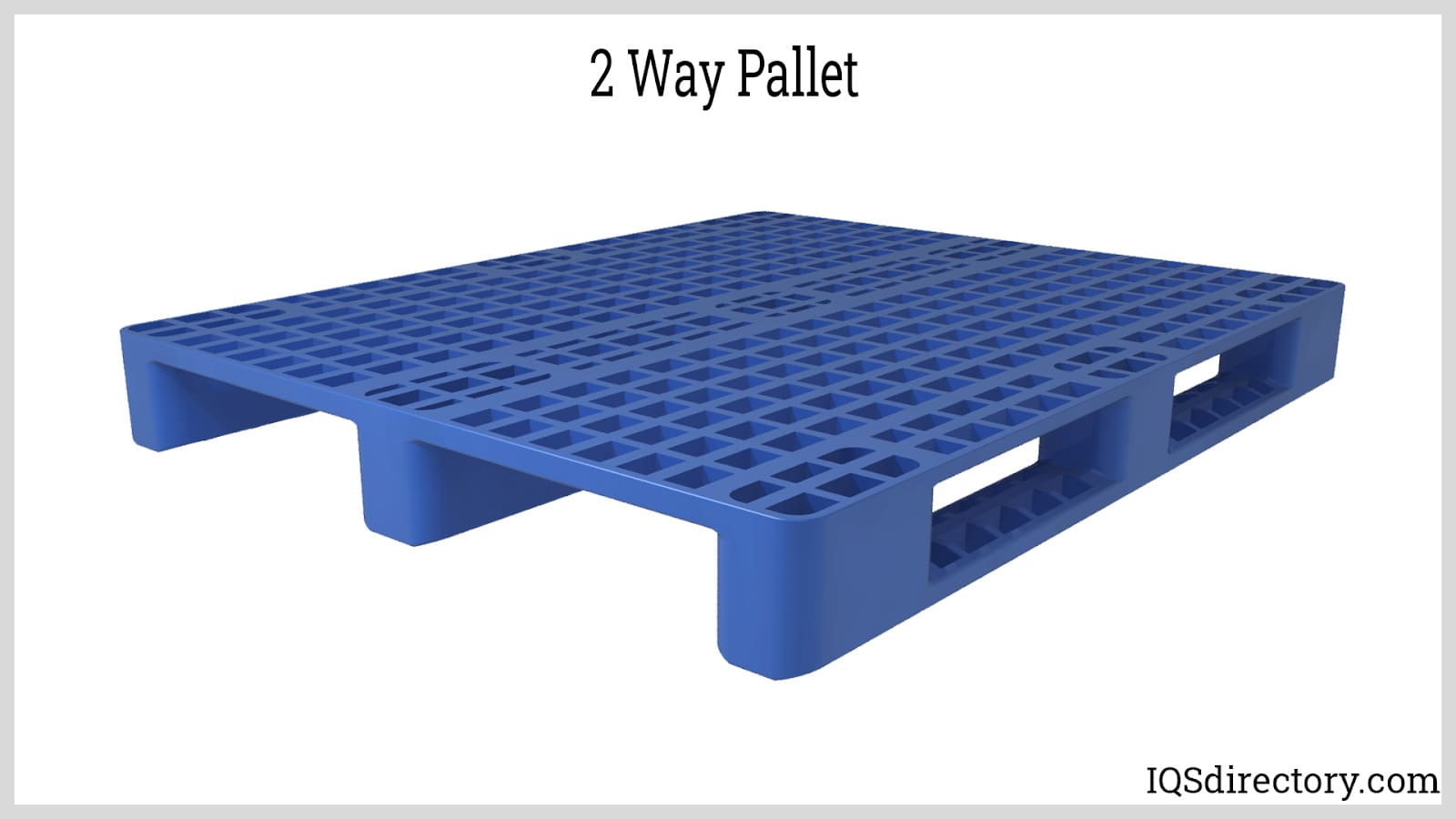

Two-Way Entry

Two-way entry pallets are designed with openings on two opposite sides of the pallet, where the forklift of the carrying mechanism lifts the pallet.

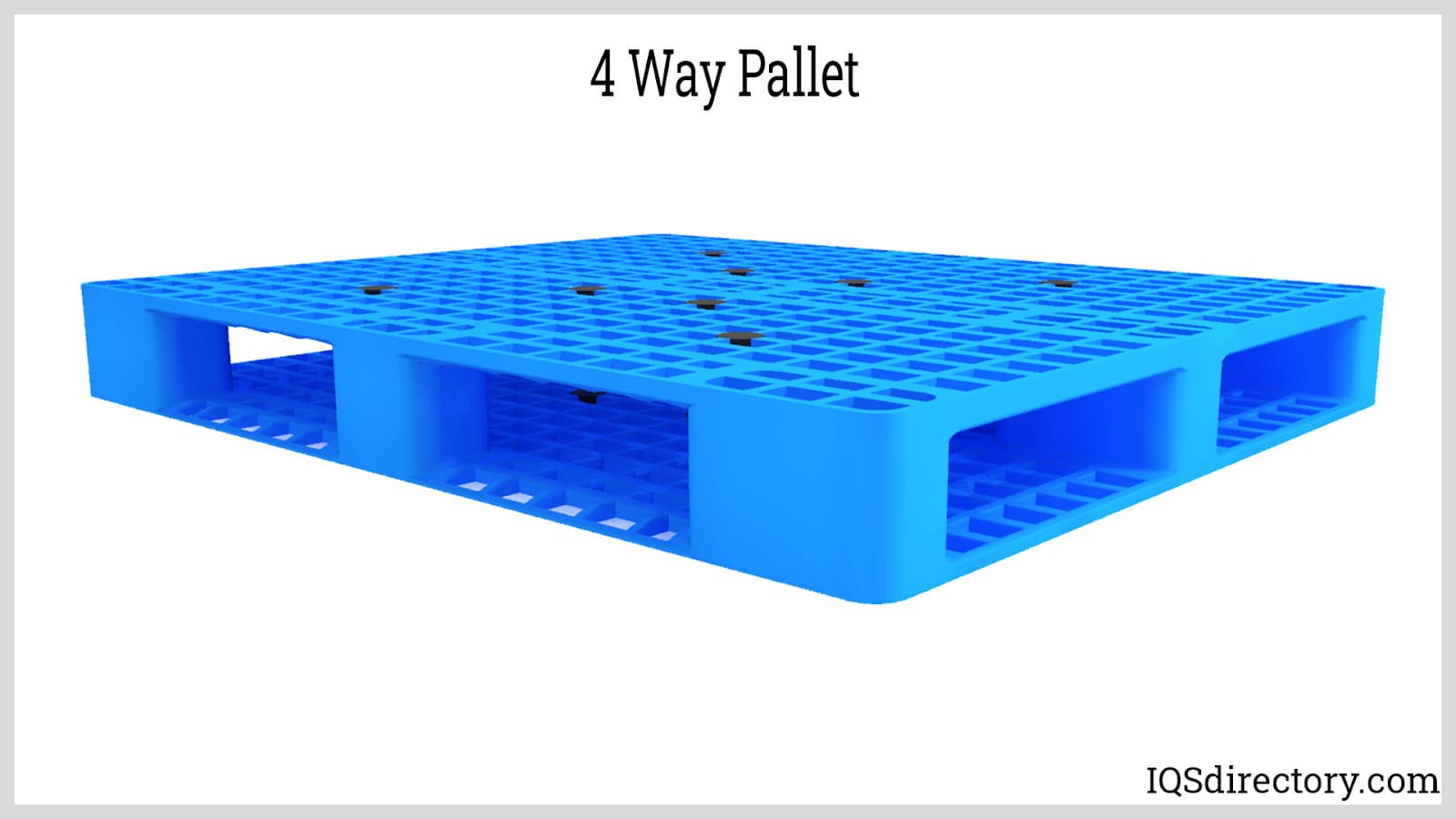

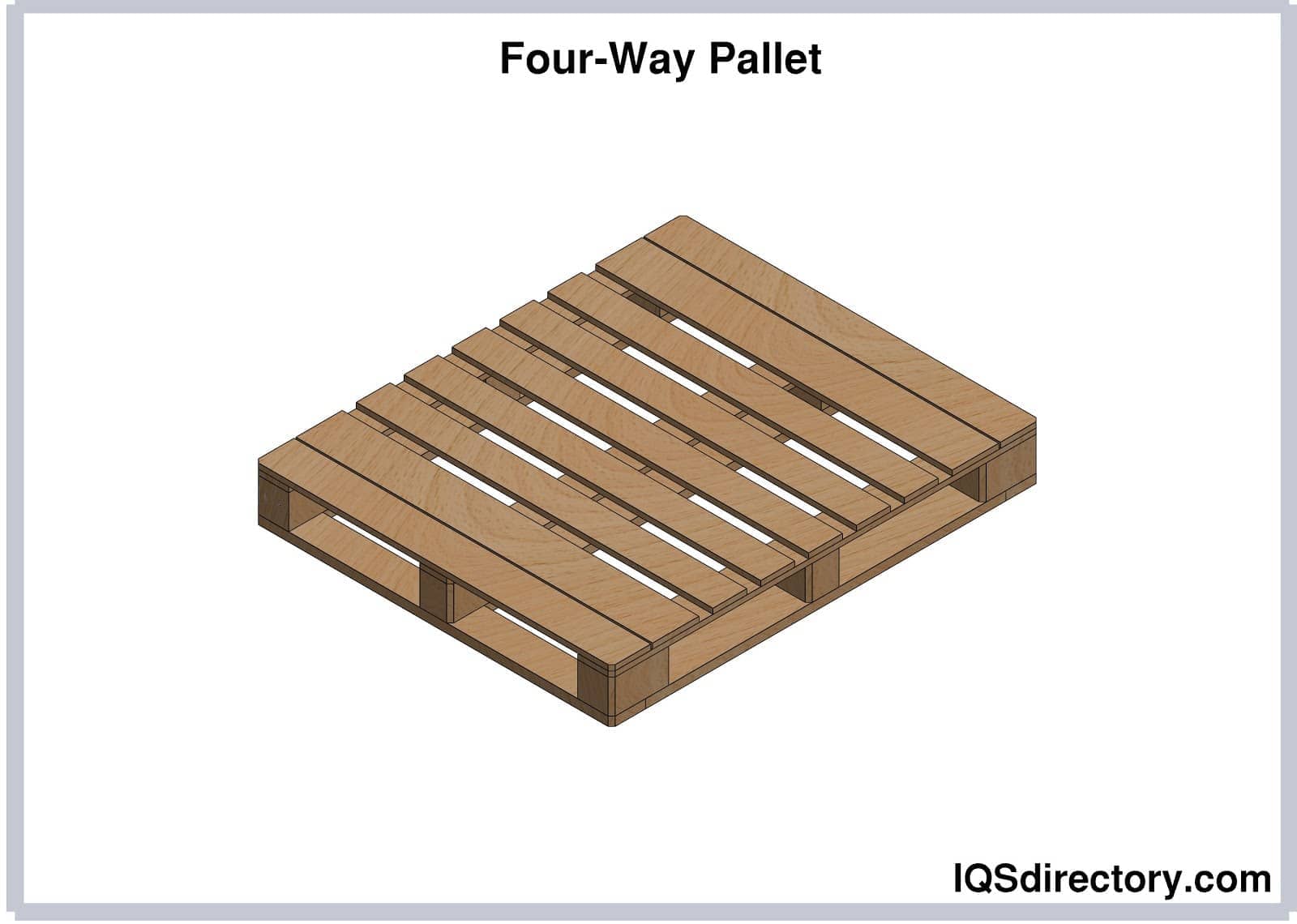

Four-Way Entry

Four-way entry pallets have openings on all four sides and can be accessed by the forklift from either side. However, they are less robust and have lesser weight-bearing ability than the two-way entry pallets.

Open Deck Pallet

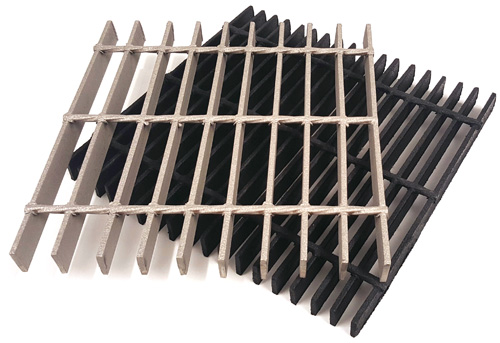

Open deck pallets have gaps in between the deck boards. The gaps greatly reduce the weight and density of the structure, making them relatively inexpensive. They cannot be used in the carriage of smaller items as they would fall off.

Solid Deck Pallet

These pallets are made of a single sheet of plastic without any gaps. Solid deck pallets are easy to handle, clean, and transport. Unlike open deck pallets, they are ideal for the carriage of small goods.

Double Face Pallet

Unlike solid deck pallets, double face pallets come with a top and bottom face. The extra deck increases the strength and convenience of using it as it counteracts and distributes the entire load placed on it.

Applications and Benefits of Recycled Pallets

The applications and benefits of recycled pallets include:

Applications of Recycled Pallets

The main use of recycled pallets is in transporting goods in factories and warehouses. For example, goods like packets of medical supplies and cartons of liquid products are carefully laid on pallets and transported from one point to the other through forklifts and pallet jacks. The military uses plastic pallets to pack military supplies and even vehicles, which are then loaded into airplanes that are later dropped at high altitudes with parachutes. Plastic pallets are used because they are lighter and can withstand the impact upon reaching the ground. Recycled pallets are also used for displaying commercial products. Retailers and vendors use pallets to pack and display their products so that customers can easily identify and take desired goods.

Benefits of Recycled Pallets

Pallets are cheap to manufacture. Old pallets and other plastics can be used to make new pallets, making production and manufacturing very cheap. Recycled plastic pallets have a long lifespan since their area of usage does not involve rapidly moving parts that bring about wear and tear. Plastic pallets are also very easy to transport because they are flexible and versatile and can be used in numerous applications. The pallets are also hygienic and safer for everyone.

Choosing the Right Recycled Pallet Supplier

To ensure you have the most positive outcome when purchasing recycled pallets from a recycled pallet supplier, it is important to compare several companies using our directory of recycled pallet suppliers. Each recycled pallet supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to communicate with the supplier for more information or request a quote. Review each recycled pallet business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple recycled pallet companies with the same form.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

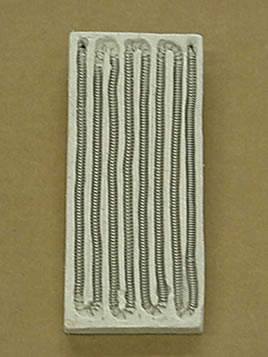

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches