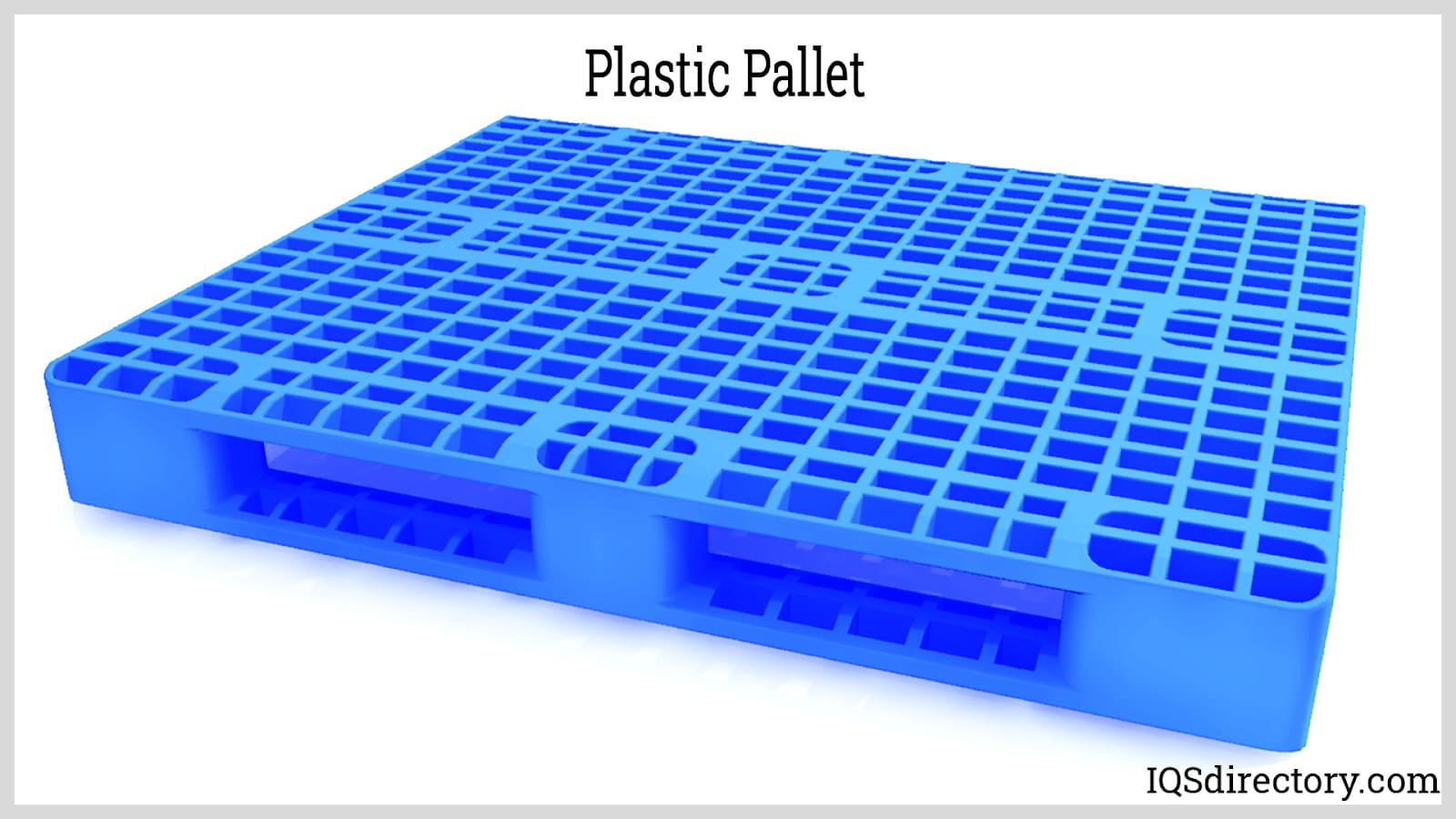

Custom pallets are essential to many industrial processes. For example, food processing and pharmaceutical companies’ products must comply with FDA standards of cleanliness and safety; custom pallets can be engineered with bacterial-resistant properties and chemical-inertness. Read More…

TMF Corporation manufactures and supplies the Protech 4048 heavy duty plastic pallet. With inventory on hand, we have the ability quickly deliver and pallets we have in stock, including the FM approved Protech 4048 with color options, four-way entry and more.

At Premier Handling Solutions, we provide warehouse equipment solutions that improve overall productivity, safety and speed throughout the manufacturing, warehousing, distribution, consumption, storage and disposal process. Browse our selection of pallets, inverters, tippers, wire containers, and pallet dispensers to find the perfect product for your application.

At Peninsula Plastics, you can find high-performance, vacuum-formed reusable plastic pallets for maximum strength and durability. Our economical twin-sheet & single-sheet pallets feature nestable and stackable models, large load capacity, many sizes, guaranteed acceptance at all ports, use in demanding applications, and with automated systems.

At Craemer US Corporation, we specialize in providing comprehensive solutions for plastic pallets tailored to meet the diverse needs of our clientele. With decades of experience and a commitment to excellence in the plastics industry, we have established ourselves as a trusted leader in plastic pallet manufacturing, renowned for our dedication to quality, innovation, and customer satisfaction....

Robinson Industries reduces operational costs and worker injuries through providing superior-quality plastic pallets. We sell pallets in a variety of sizes and styles. Robinson Industries is ready and able to meet diverse industry needs.

Fibertech Plastic pallets are an excellent alternative to wood pallets, offering cost-efficient solutions for strong, durable & washable pallets. Our unique angled leg design helps reduce forklift damage by enabling the fork tines to deflect off the leg rather than breaking or cutting the pallet. An optional lip prevents product slippage & facilitates transportation of stacked, empty pallets.

More Custom Pallet Manufacturers

Some manufacturers also must meet safety standards, and custom pallets can improve workplace safety when designed with flame-retardant and corrosion-resistant properties. Custom plastic pallets are typically constructed from high density polyethylene, which is a strong, durable plastic material, though high density polypropylene may be used as well.

Compliance with health and safety regulations isn't the only motivation behind the demand for custom plastic pallets. Many companies with large scale distribution operations, like food and beverage suppliers, want their brand identity to be recognizable in the pallets that bear their products. Pallets can be fabricated in many colors and can feature printed company names.

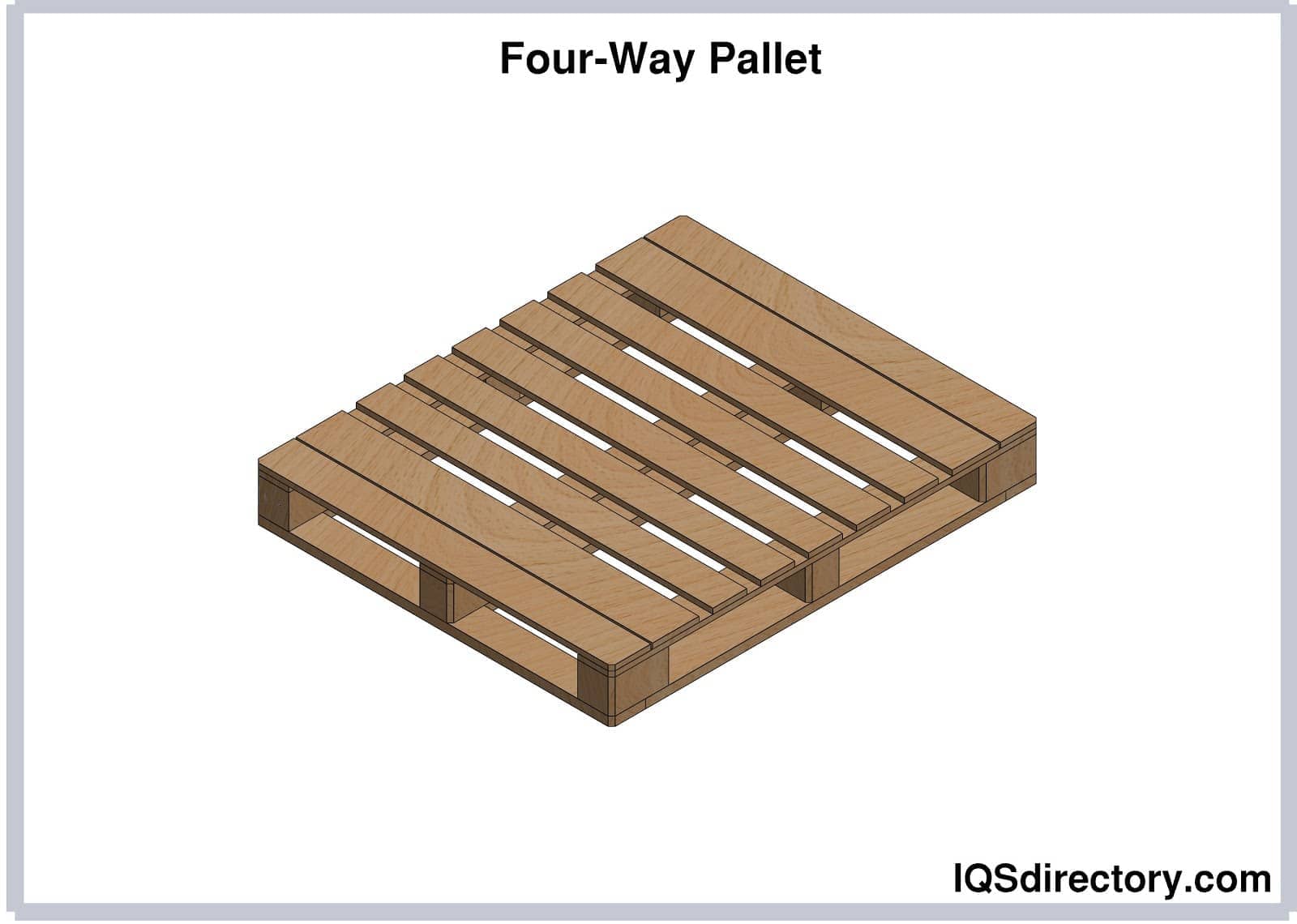

Custom pallets can be formed through six different plastic fabrication processes: injection molding, compression molding, rotational molding, profile extrusion, thermoforming and structural foam molding.

The most commonly used processes are injection molding and compression molding. In injection molding, plastic pellets are heated to the melting point, then injected into the cavity of a split die or mold that is then clamped shut. The molten plastic is cooled and held in the mold under high pressure until it solidifies.

In compression molding, plastic pellets are heated to their melting point and then placed in an open, heated mold chamber. The mold is then closed with either a top force or plug member, and extreme pressure is applied to the mold. The pressure forces the molten plastic material into contact with every area of the mold, and the heat and pressure are maintained until the molded plastic has cured.

Additives can be combined with the plastic pallets during heating in order to give the plastic pallets additional benefits like UV-protection or increased durability. The mold may also be designed to give the pallet a specific shape to accommodate unique products.

55 Gallon Drums

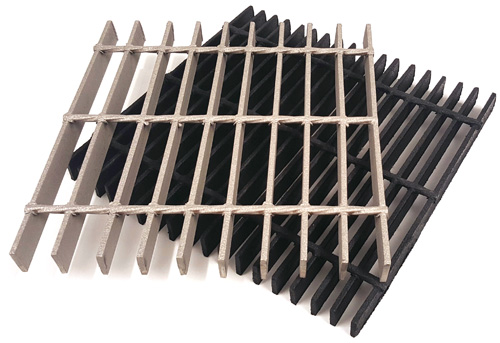

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches