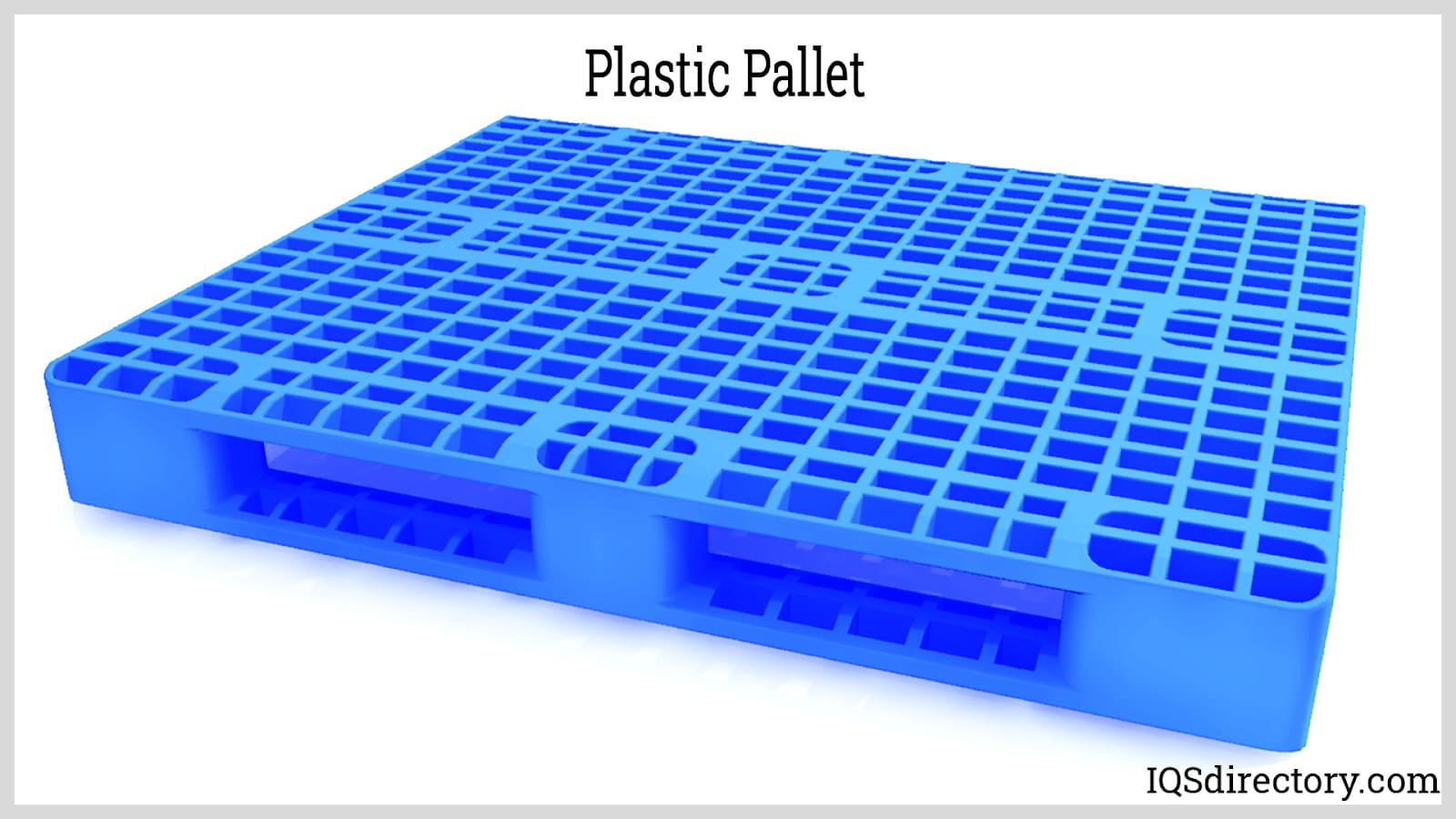

Plastic skids are an important component of modern-day logistics, helping companies transport goods and products more efficiently. They are lightweight, durable, and can be used multiple times, making them a popular alternative to traditional wooden or metal skids. Read More…

TMF Corporation manufactures and supplies the Protech 4048 heavy duty plastic pallet. With inventory on hand, we have the ability quickly deliver and pallets we have in stock, including the FM approved Protech 4048 with color options, four-way entry and more.

At Premier Handling Solutions, we provide warehouse equipment solutions that improve overall productivity, safety and speed throughout the manufacturing, warehousing, distribution, consumption, storage and disposal process. Browse our selection of pallets, inverters, tippers, wire containers, and pallet dispensers to find the perfect product for your application.

At Peninsula Plastics, you can find high-performance, vacuum-formed reusable plastic pallets for maximum strength and durability. Our economical twin-sheet & single-sheet pallets feature nestable and stackable models, large load capacity, many sizes, guaranteed acceptance at all ports, use in demanding applications, and with automated systems.

At Craemer US Corporation, we specialize in providing comprehensive solutions for plastic pallets tailored to meet the diverse needs of our clientele. With decades of experience and a commitment to excellence in the plastics industry, we have established ourselves as a trusted leader in plastic pallet manufacturing, renowned for our dedication to quality, innovation, and customer satisfaction....

Robinson Industries reduces operational costs and worker injuries through providing superior-quality plastic pallets. We sell pallets in a variety of sizes and styles. Robinson Industries is ready and able to meet diverse industry needs.

Fibertech Plastic pallets are an excellent alternative to wood pallets, offering cost-efficient solutions for strong, durable & washable pallets. Our unique angled leg design helps reduce forklift damage by enabling the fork tines to deflect off the leg rather than breaking or cutting the pallet. An optional lip prevents product slippage & facilitates transportation of stacked, empty pallets.

More Plastic Skid Manufacturers

Plastic skids were first developed in the early 1960s as an alternative to traditional wooden skids. Their popularity grew quickly because of their durability, long life, and cost-effectiveness. Early plastic skids were made using thermoplastic resin, but advancements in technology led to the development of newer, more robust materials.

Plastic Skids vs. Plastic Pallets

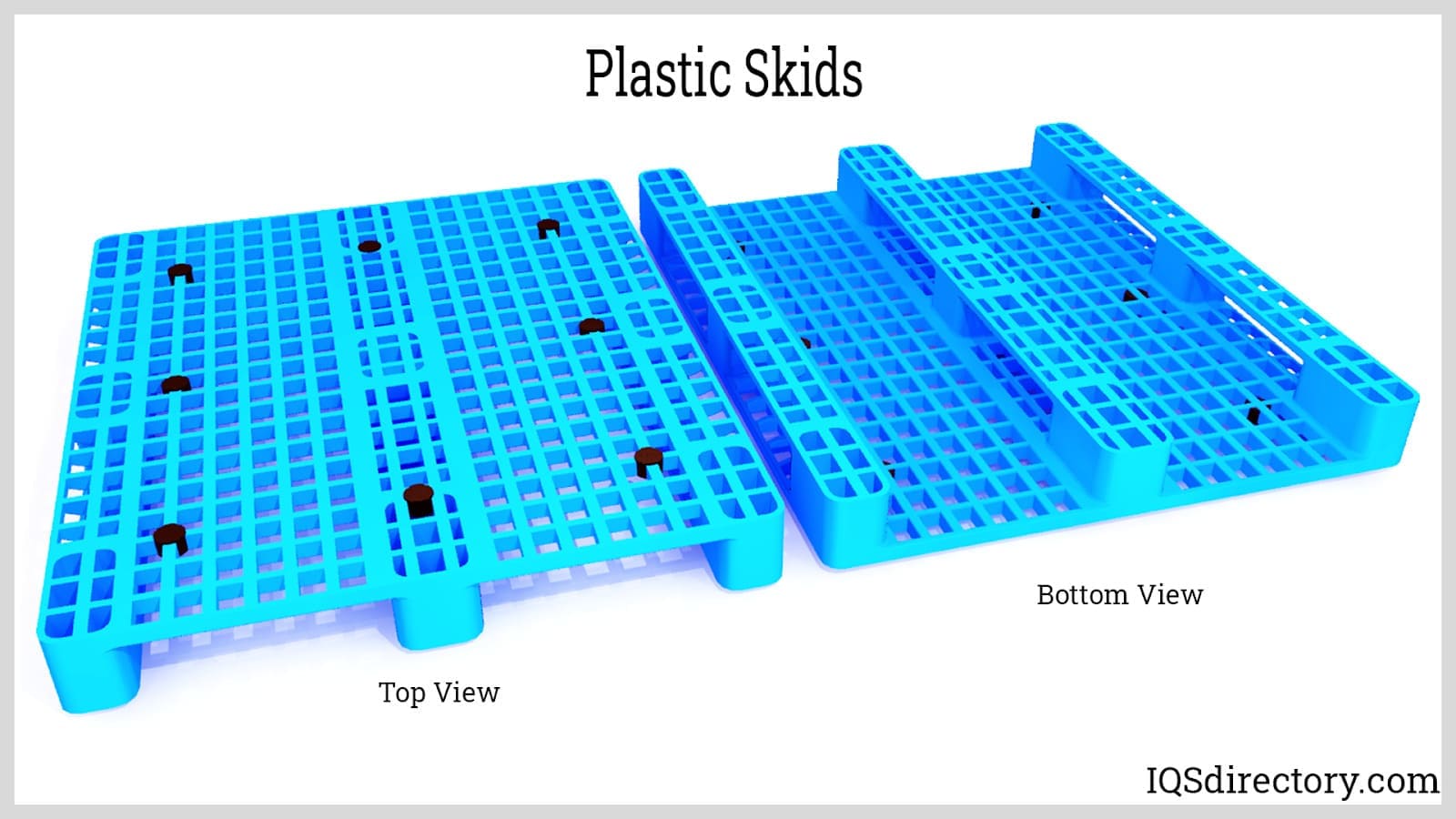

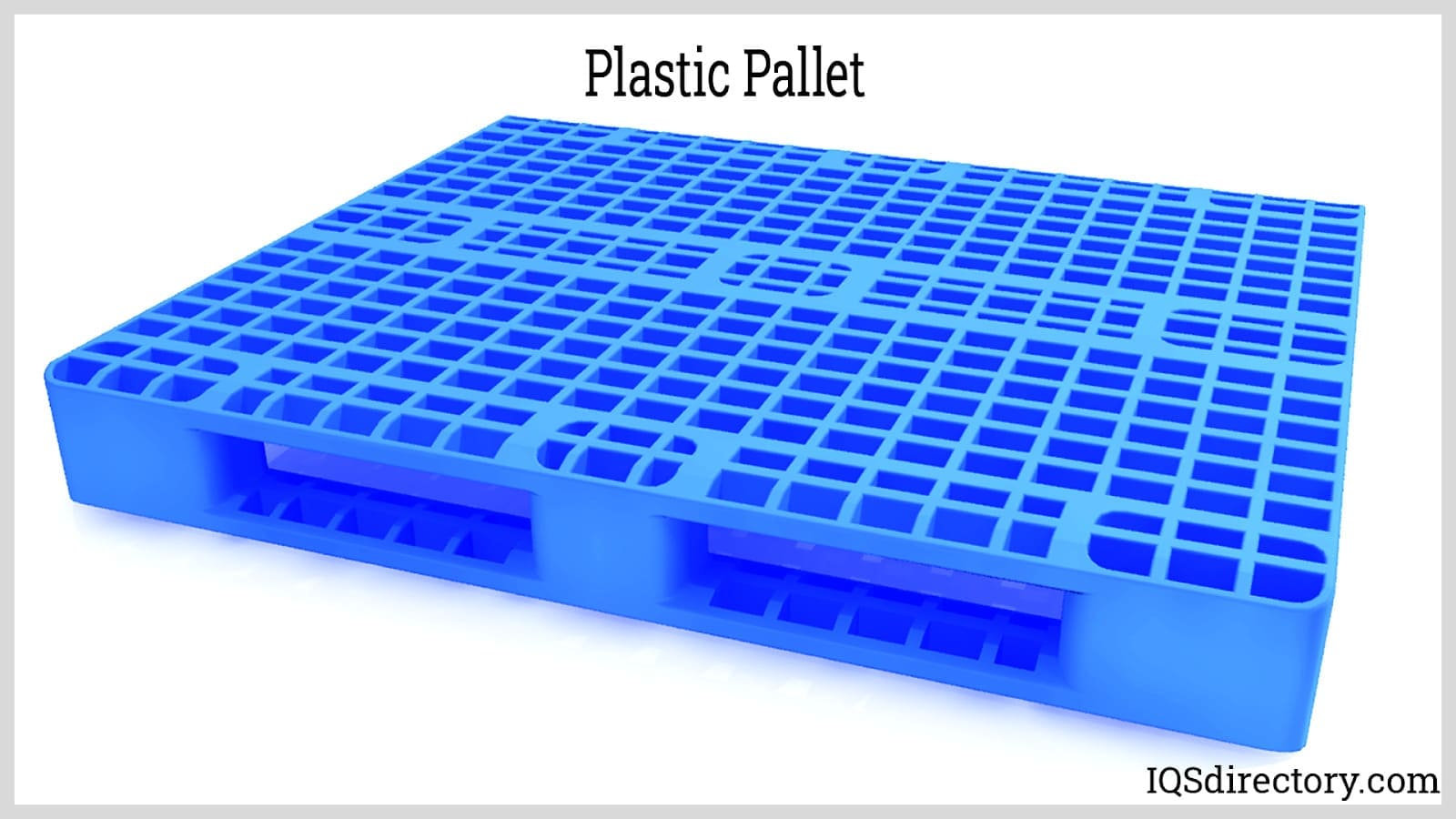

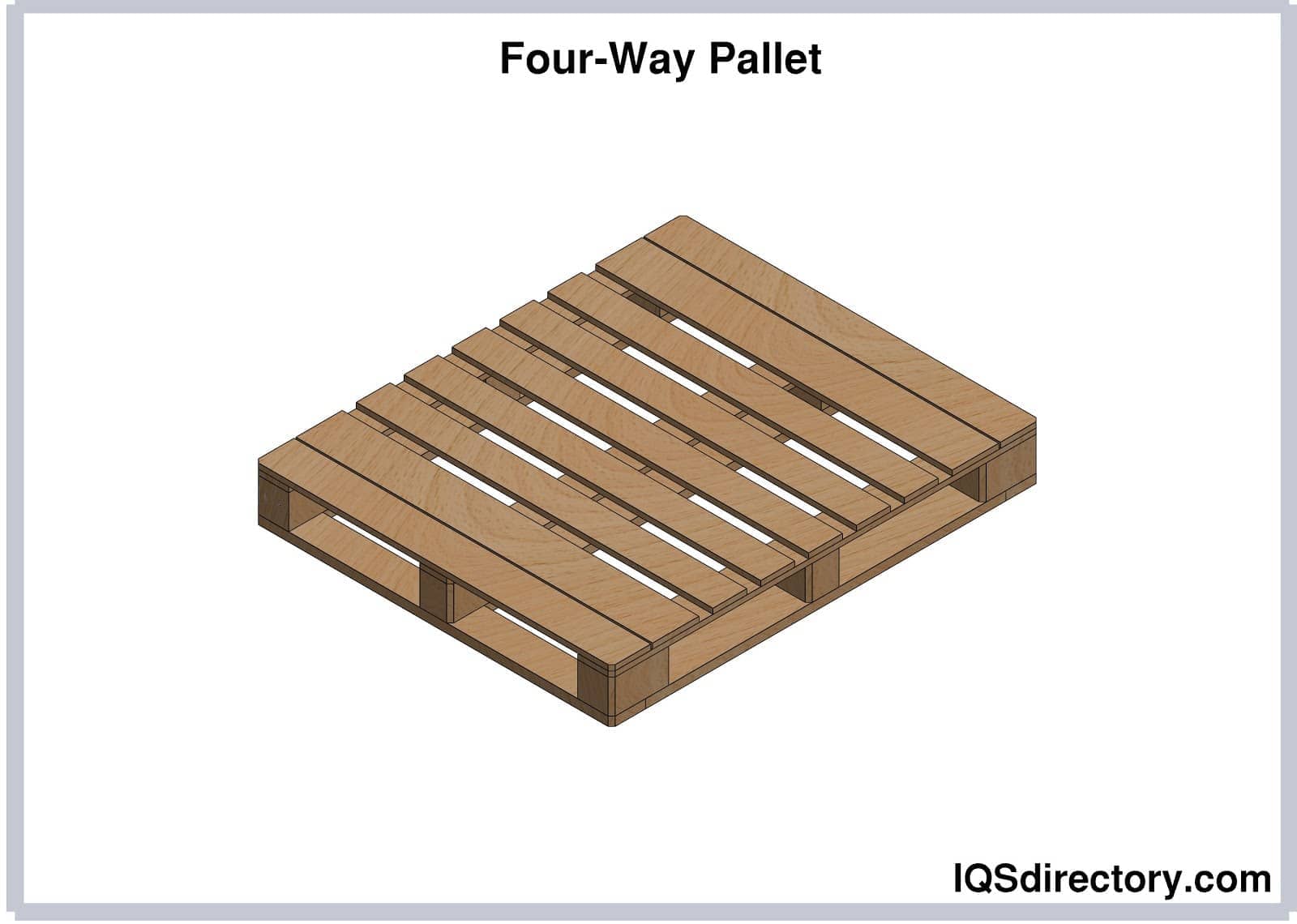

While plastic skids and plastic pallets are often used interchangeably, there are some differences between the two. Plastic skids are flat, low-profile structures that have no bottom deck boards, whereas pallets have top and bottom deck boards. Skids are also designed to support products that do not require a full deck support system, whereas pallets can support any type of product. Plastic skids are therefore ideal for light to medium weight loads, whereas pallets are better suited for heavier loads.

Creating Plastic Skids

Plastic skids are typically created through a process known as injection molding. Thermoforming is another popular method used to create plastic skids. Both of these processes, and the benefits they both provide when creating plastic skids, are explained below.

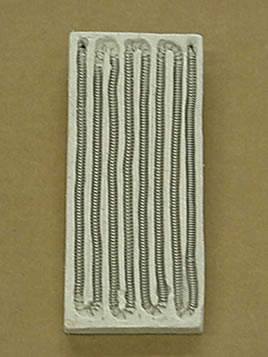

Injection Molding

Injection molding is a popular method used to create plastic skids. This process involves melting plastic pellets and injecting them into a mold, where they are left to cool and harden into the desired shape. Injection molding can be used to create skids in various sizes, shapes, and colors, making it a versatile method of production.

One of the benefits of injection molding is that it produces high-quality, durable plastic skids that can withstand repeated use and exposure to harsh conditions. The process is also fast and efficient, with high-volume production capabilities, making it an ideal method for mass-producing plastic skids for commercial use. Additionally, injection molding can produce complex geometries and custom designs, allowing manufacturers to create skids that meet specific customer requirements.

Thermoforming

Thermoforming is another popular method used to create plastic skids. This process involves heating a sheet of plastic until it is soft and pliable, and then molding it into the desired shape. The plastic is then cooled and hardened, resulting in a high-quality, durable skid. Thermoforming is commonly used to create smaller-sized plastic skids.

One of the benefits of thermoforming is that it allows manufacturers to create skids with varying thicknesses, which can be useful in applications that require specific weight restrictions or load capacities. Thermoforming also allows for more flexibility in design, making it easier to create custom shapes and sizes. Additionally, thermoformed plastic skids are typically more affordable than injection-molded skids, making them a good option for smaller businesses or startups.

Suitable Applications for Each Method

Both injection molding and thermoforming are suitable for creating plastic skids, but the choice of method will depend on specific application requirements. Injection molding is best suited for high-volume production runs of larger-sized plastic skids, while thermoforming is better suited for smaller-sized skids and lower volume runs. Additionally, injection molding is more appropriate for applications that require custom designs and complex geometries.

Limits and Negatives Associated with Plastic Skids

One potential limitation of plastic skids is their load capacity. They are not designed to support extremely heavy loads and may crack or break under excessive weight. Another limitation is their environmental impact. While plastic skids are recyclable, they may take longer to decompose than wooden skids and can contribute to plastic waste.

Benefits of Plastic Skids

One of the main benefits of plastic skids is their durability. They are resistant to moisture, chemicals, and pests, and can withstand harsh environments. They are also lightweight and easy to handle, which makes them ideal for automated processes such as conveyor systems. Additionally, plastic skids are reusable, reducing the need for constant replacement and reducing waste.

Applications of Plastic Skids

Plastic skids are used in a variety of industries, including warehousing and transportation, manufacturing, the food and beverage industry, the automotive industry, and in the retail, electronics, and pharmaceutical sectors. Each of these specific applications is explained below.

Warehousing and Transportation

Plastic skids are commonly used in warehousing and transportation due to their lightweight yet durable nature. They are easy to handle and can withstand repeated use, making them an ideal choice for material handling and storage. Additionally, plastic skids are resistant to moisture, mold, and insects, which makes them an excellent choice for storing goods that require protection from these elements.

Manufacturing

Plastic skids are frequently used in manufacturing due to their ability to handle heavy loads and resistance to impact and abrasion. They are also easy to clean and sanitize, making them suitable for use in cleanroom environments. Additionally, plastic skids can be customized to meet specific manufacturing needs, such as anti-slip surfaces or specialized dimensions.

Food and Beverage Industry

Plastic skids are an ideal choice for the food and beverage industry due to their resistance to moisture, mold, and bacteria. They are also easy to clean and sanitize, making them suitable for use in food processing and storage environments. Additionally, plastic skids can be customized with specific design features to meet food safety regulations, such as ventilation for perishable items or integrated drain holes.

Automotive Industry

Plastic skids are frequently used in the automotive industry due to their lightweight yet durable nature. They are ideal for moving heavy automotive parts and components, and can also be used for storing and transporting finished vehicles. Additionally, plastic skids can be customized with specific features to protect delicate or sensitive automotive parts during transportation or storage.

Retail, Electronics, and Pharmaceutical Sectors

Plastic skids are commonly used in the retail, electronics, and pharmaceutical sectors due to their resistance to moisture, mold, and bacteria. They are also ideal for moving and storing fragile or delicate products, as they can be customized with anti-slip surfaces or specialized designs to prevent damage during transportation or storage. Additionally, plastic skids can be easily cleaned and sanitized, making them suitable for use in cleanroom environments.

Choosing the Right Plastic Skid Supplier

To ensure you have the most productive outcome when purchasing plastic skids from a plastic skid supplier, it is important to compare several companies using our directory of plastic skid suppliers. Each plastic skid supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to contact the supplier for more information or request a quote. Review each plastic pallet business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple plastic skid companies with the same form.

55 Gallon Drums

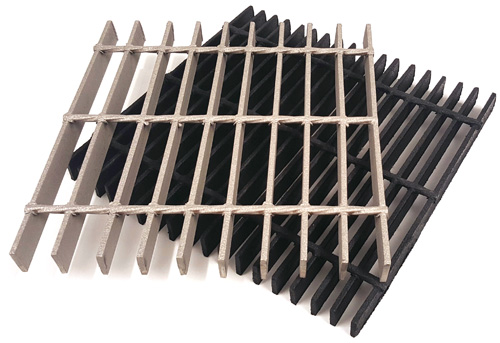

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches