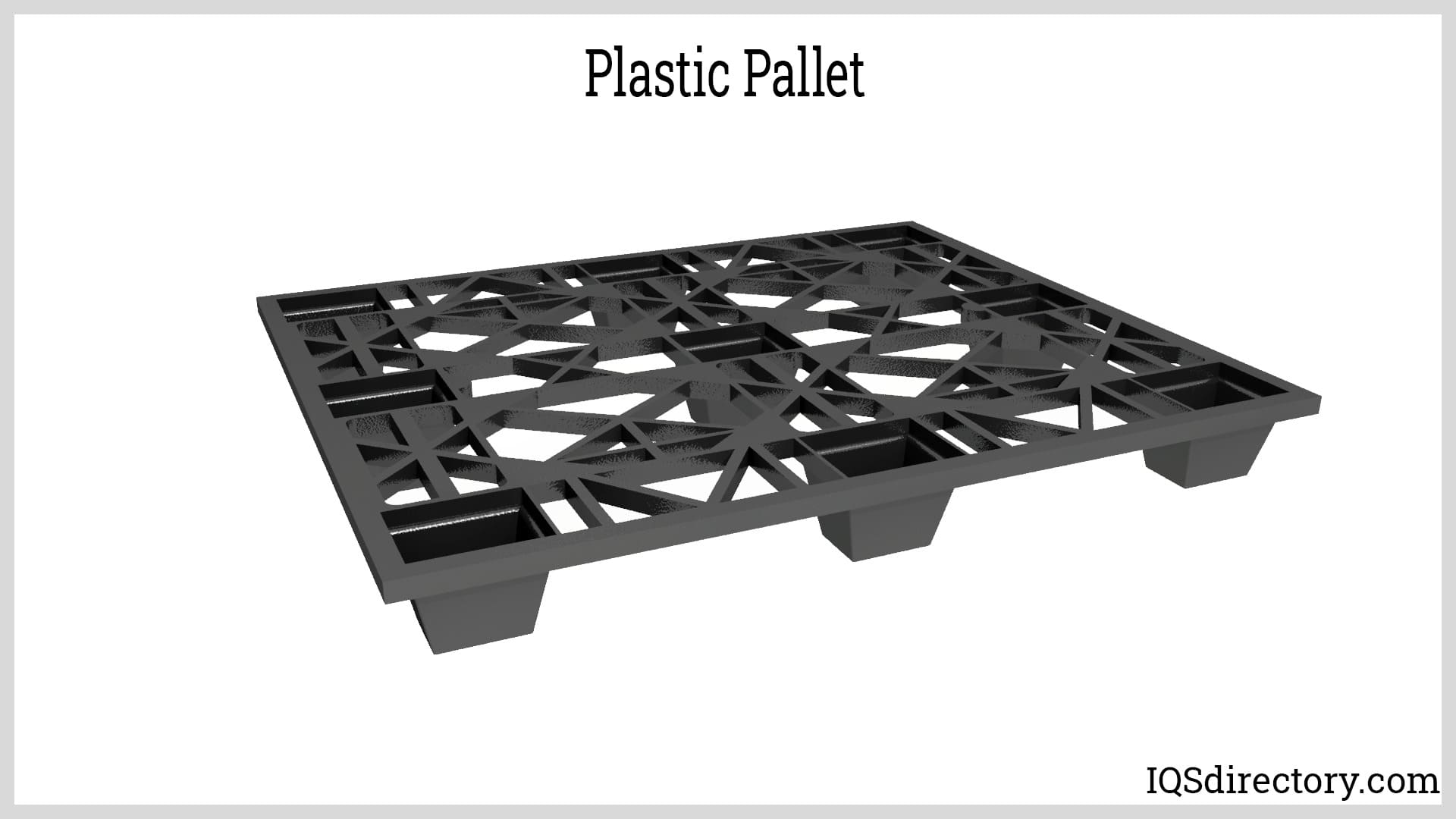

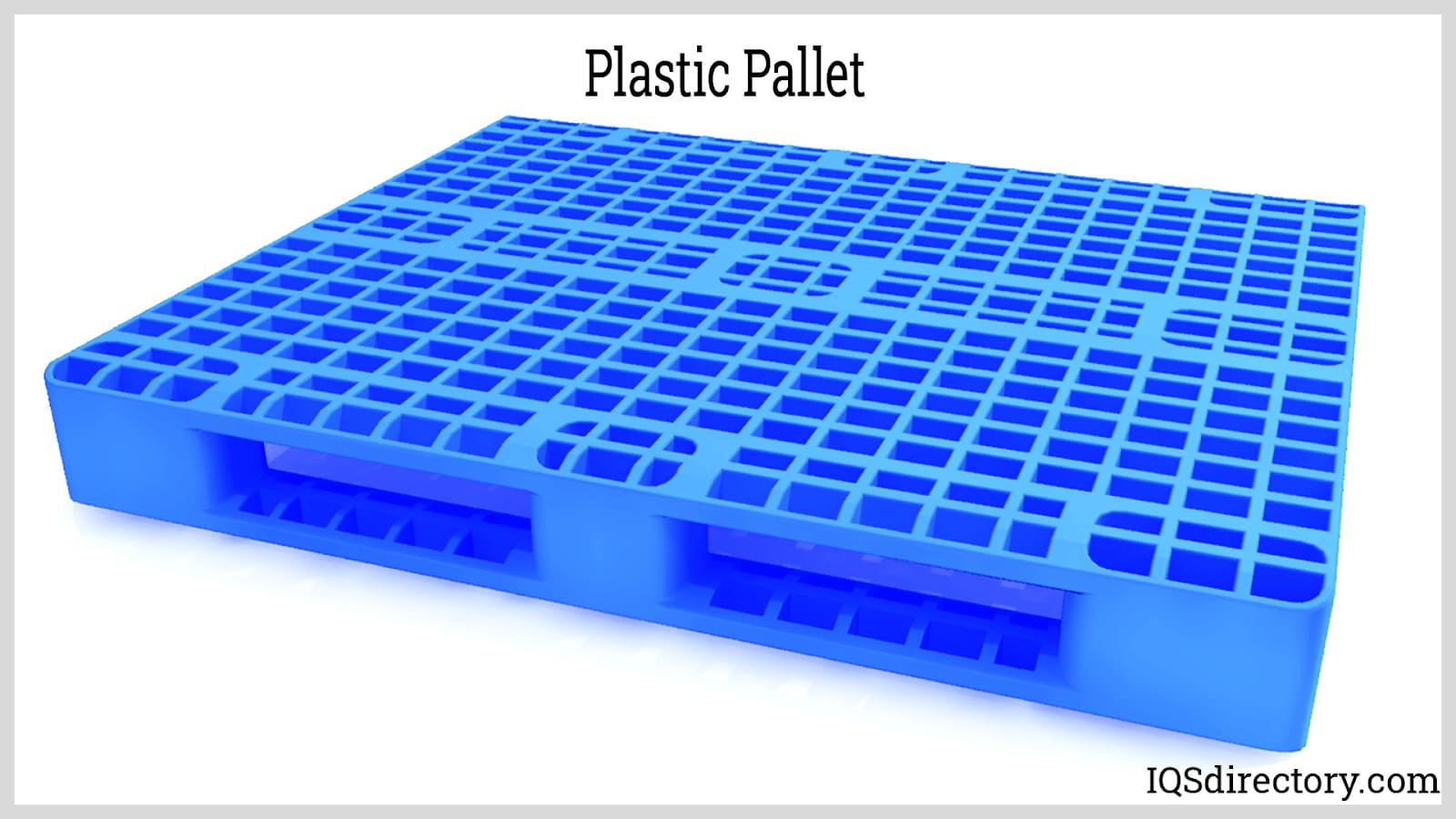

Plastic pallets are a type of pallet made entirely of plastic, which is a synthetic material composed of polymers that are capable of being molded into various shapes and sizes. Plastic pallets were created in response to several issues associated with traditional wooden pallets. For example, wooden pallets are often susceptible to rot, splinters, and damage from exposure to moisture. They can also be difficult to clean and are susceptible to insect infestations. Plastic pallets, on the other hand, are resistant to these issues and can be easily cleaned with a pressure washer. As a result, they have gained popularity in recent years over traditional wooden pallets. Read More…

TMF Corporation manufactures and supplies the Protech 4048 heavy duty plastic pallet. With inventory on hand, we have the ability quickly deliver and pallets we have in stock, including the FM approved Protech 4048 with color options, four-way entry and more.

At Premier Handling Solutions, we provide warehouse equipment solutions that improve overall productivity, safety and speed throughout the manufacturing, warehousing, distribution, consumption, storage and disposal process. Browse our selection of pallets, inverters, tippers, wire containers, and pallet dispensers to find the perfect product for your application.

At Peninsula Plastics, you can find high-performance, vacuum-formed reusable plastic pallets for maximum strength and durability. Our economical twin-sheet & single-sheet pallets feature nestable and stackable models, large load capacity, many sizes, guaranteed acceptance at all ports, use in demanding applications, and with automated systems.

At Craemer US Corporation, we specialize in providing comprehensive solutions for plastic pallets tailored to meet the diverse needs of our clientele. With decades of experience and a commitment to excellence in the plastics industry, we have established ourselves as a trusted leader in plastic pallet manufacturing, renowned for our dedication to quality, innovation, and customer satisfaction....

Robinson Industries reduces operational costs and worker injuries through providing superior-quality plastic pallets. We sell pallets in a variety of sizes and styles. Robinson Industries is ready and able to meet diverse industry needs.

Fibertech Plastic pallets are an excellent alternative to wood pallets, offering cost-efficient solutions for strong, durable & washable pallets. Our unique angled leg design helps reduce forklift damage by enabling the fork tines to deflect off the leg rather than breaking or cutting the pallet. An optional lip prevents product slippage & facilitates transportation of stacked, empty pallets.

More Plastic Pallet Manufacturers

Types of Plastics Used to Make Pallets

Common plastics used for plastic pallets include:

High-Density Polyethylene (HDPE): Known for its strength and durability, HDPE is ideal for heavy-duty applications. It resists impact and can handle high loads effectively.

Polypropylene (PP): This lightweight and cost-effective plastic offers good chemical resistance, making it a popular choice for plastic pallets.

Polyethylene Terephthalate (PET): PET is a durable plastic used in injection-molded pallets. It handles high temperatures well and has excellent chemical resistance, making it suitable for industries such as pharmaceuticals and food.

Polycarbonate (PC): PC is a high-strength plastic known for its superior impact resistance. It also offers resistance to heat and chemicals.

Acrylonitrile Butadiene Styrene (ABS): ABS is a robust plastic with high impact resistance and good chemical durability. It can withstand elevated temperatures, making it a reliable choice for demanding applications.

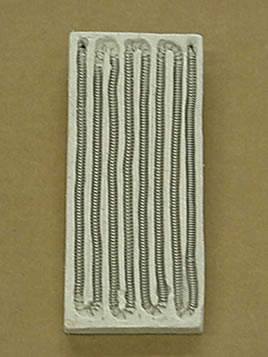

Processes Used to Make Plastic Pallets

There are three main methods for manufacturing plastic pallets: injection molding, structural foam molding, and thermoforming. Each method offers distinct advantages, outlined below:

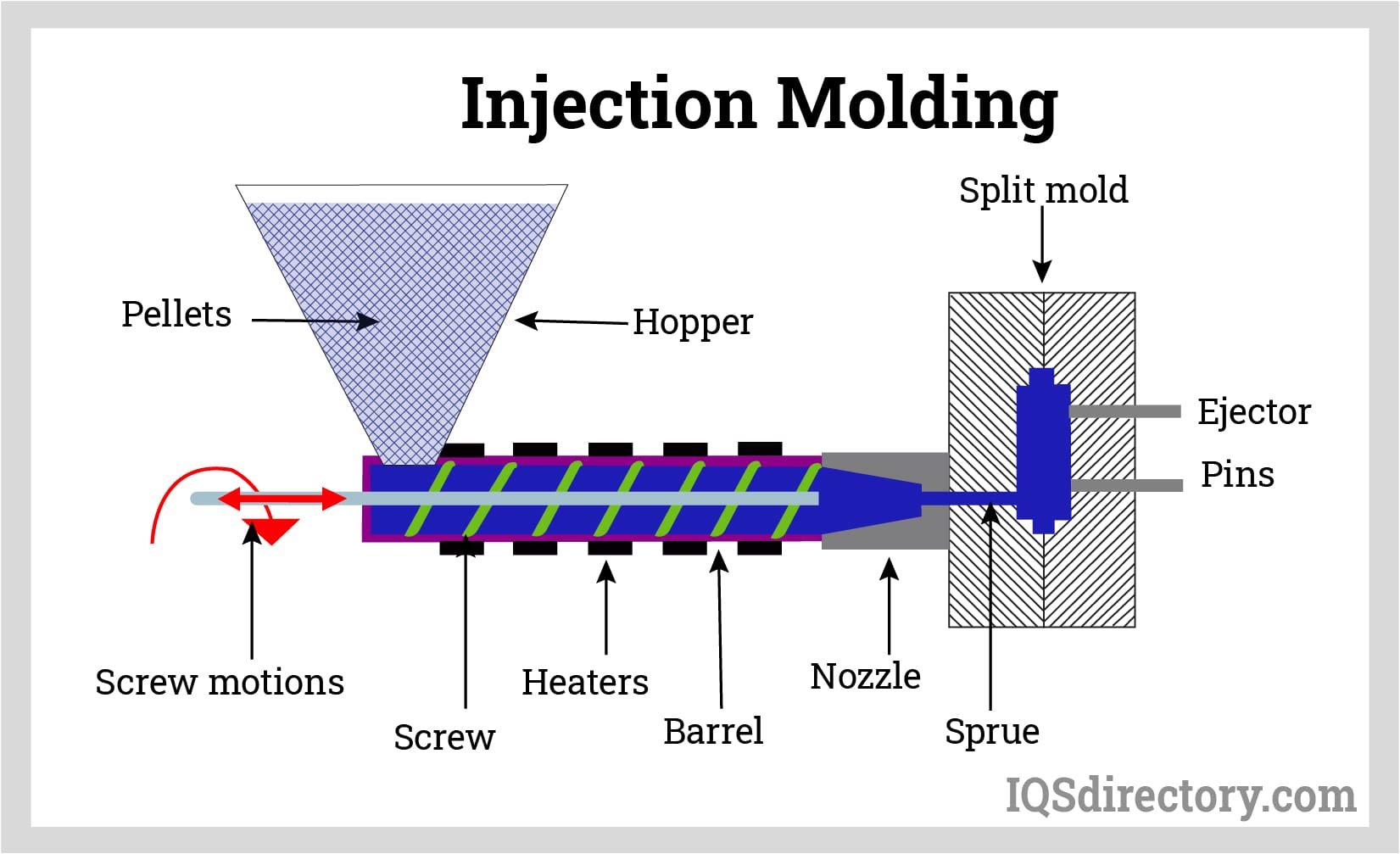

Injection Molding: This is the most widely used method for producing plastic pallets. It involves injecting molten plastic into a mold where it cools and solidifies. Key benefits of injection molding include:

- High Precision: It provides precise control over the dimensions and shape of the pallets, ensuring uniformity and accuracy.

- High Strength: Pallets produced via injection molding are more robust and durable, suitable for heavy-duty applications.

- Versatility in Sizes and Shapes: It accommodates a broad range of sizes and shapes, making it versatile for various uses.

- Cost-Effectiveness: Ideal for large-scale production, this method is economically efficient.

Structural Foam Molding: This technique incorporates a foaming agent into the plastic before injection into the mold. Its advantages are:

- Reduced Weight: The foaming agent lightens the pallets, making them easier to handle and transport.

- Enhanced Impact Resistance: These pallets withstand impact better than solid plastic ones, making them ideal for rough handling and heavy loads.

- Lower Material Costs: Less plastic is needed per pallet due to the foaming agent, which reduces material expenses.

b>Thermoforming: This method involves heating a sheet of plastic and forming it into shape using a mold. Benefits include:

- Lower Tooling Costs: Molds for thermoforming are less expensive than those for injection molding, making it a cost-effective choice for smaller production runs.

- Customization: It allows for significant customization, accommodating specific size and shape requirements.

- Reduced Waste: Thermoforming generates less waste as excess plastic can be recycled.

Beyond these advantages, plastic pallets have several additional benefits. They are more durable than wooden pallets, leading to lower replacement costs, and they resist environmental elements, making them suitable for various conditions. Moreover, they can be recycled at the end of their life, supporting sustainability and reducing waste.

Factors Determining One’s Choice of Plastic Pallets

Different types of plastic pallets are selected based on factors like intended use, load capacity, durability, weight, and cost. For instance, injection-molded pallets are favored for heavy-duty applications in industries like automotive and construction due to their high load capacity and durability. Conversely, thermoformed pallets are lightweight and cost-effective, making them well-suited for one-way shipping and export. Foam-molded pallets, though lightweight, offer a lower load capacity compared to injection-molded pallets and are best for light to medium-duty applications.

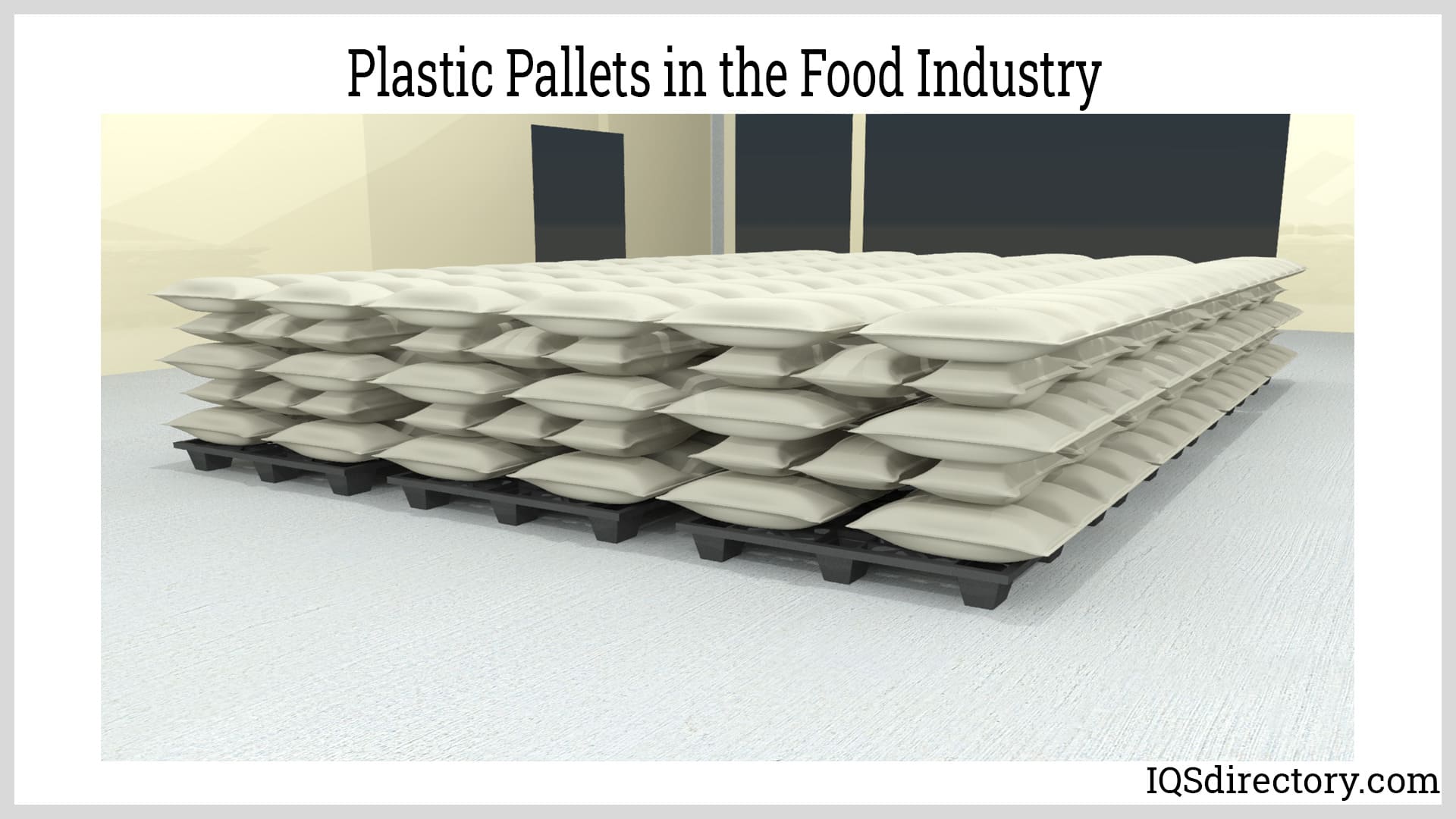

The specific requirements of the application can also dictate the choice of plastic pallet. For example, in food processing facilities where hygiene is crucial, pallets with smooth surfaces and rounded corners are preferred to minimize bacteria buildup. Compatibility with equipment is another important consideration, as some pallets may not work with automated handling systems and may require specialized equipment.

Additionally, the environmental impact of plastic pallets might be a factor. Companies may opt for pallets made from recycled materials or those that can be recycled at the end of their lifespan to support sustainability efforts and reduce waste. Ultimately, selecting the right plastic pallet involves evaluating the application’s needs, load requirements, durability, weight, cost, and environmental considerations to ensure the best choice for specific needs.

Limitations of Plastic Pallets

Plastic pallets come with several limitations. One major drawback is their higher cost compared to traditional wooden pallets. Additionally, plastic pallets generally offer less strength than wooden ones, which may make them unsuitable for some heavy-duty uses.

Environmental impact is another concern with plastic pallets. Although they are reusable and recyclable at the end of their life, they are made from non-renewable resources and can take hundreds of years to decompose in landfills. There is also the potential issue of microplastics being released into the environment during the recycling process.

Applications of Plastic Pallets

Plastic pallets are widely used across various industries due to their lightweight nature, ease of handling, and exemption from fumigation or heat treatment before export. These advantages make them a preferred choice in several sectors, including:

Food and Beverage Industry: Plastic pallets are highly suitable for the food and beverage sector due to their hygienic properties. They can be easily cleaned and sanitized, reducing the risk of food contamination. Their moisture resistance also makes them ideal for humid environments like cold storage facilities.

Pharmaceutical Industry: With stringent regulations for transporting and storing medicines and medical equipment, plastic pallets are an excellent choice for the pharmaceutical industry. Their lightweight, durable, and easy-to-clean nature meets the industry’s high standards.

Retail Industry: For retailers, plastic pallets offer ease of handling, stacking, and storage. Their lightweight and uniform size facilitate movement and stacking, while their durability ensures they can be reused multiple times.

Automotive Industry: The automotive sector demands pallets that can endure heavy loads and rough handling. Injection-molded plastic pallets are favored in this industry for their high load capacity and durability.

Construction Industry: In the construction field, strong pallets are needed to support heavy materials like bricks and cement bags. Injection-molded plastic pallets are well-suited for this purpose due to their strength and durability.

Export Industry: Plastic pallets are advantageous for the export industry because they do not require fumigation or heat treatment, unlike wooden pallets. Additionally, their lightweight nature helps lower shipping costs.

Overall, plastic pallets are valued for their versatility and efficiency across these diverse industries.

Choosing the Proper Plastic Pallets Supplier

To ensure you get the best results when buying plastic pallets, it’s crucial to compare multiple suppliers. Use our list of plastic pallet suppliers to do this effectively. Each supplier has a dedicated business profile page that showcases their expertise and capabilities, along with a contact form for direct communication or quote requests. Explore each supplier’s website with our unique website previewer to understand their specialization, and then use our easy RFQ form to send the same message to multiple companies.

55 Gallon Drums

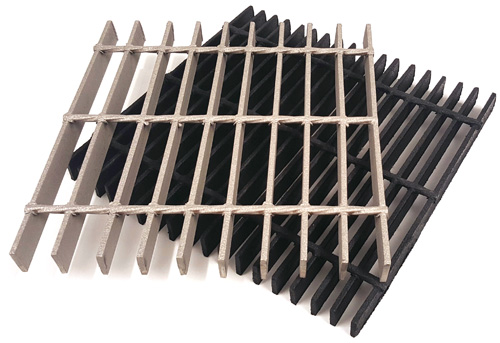

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches