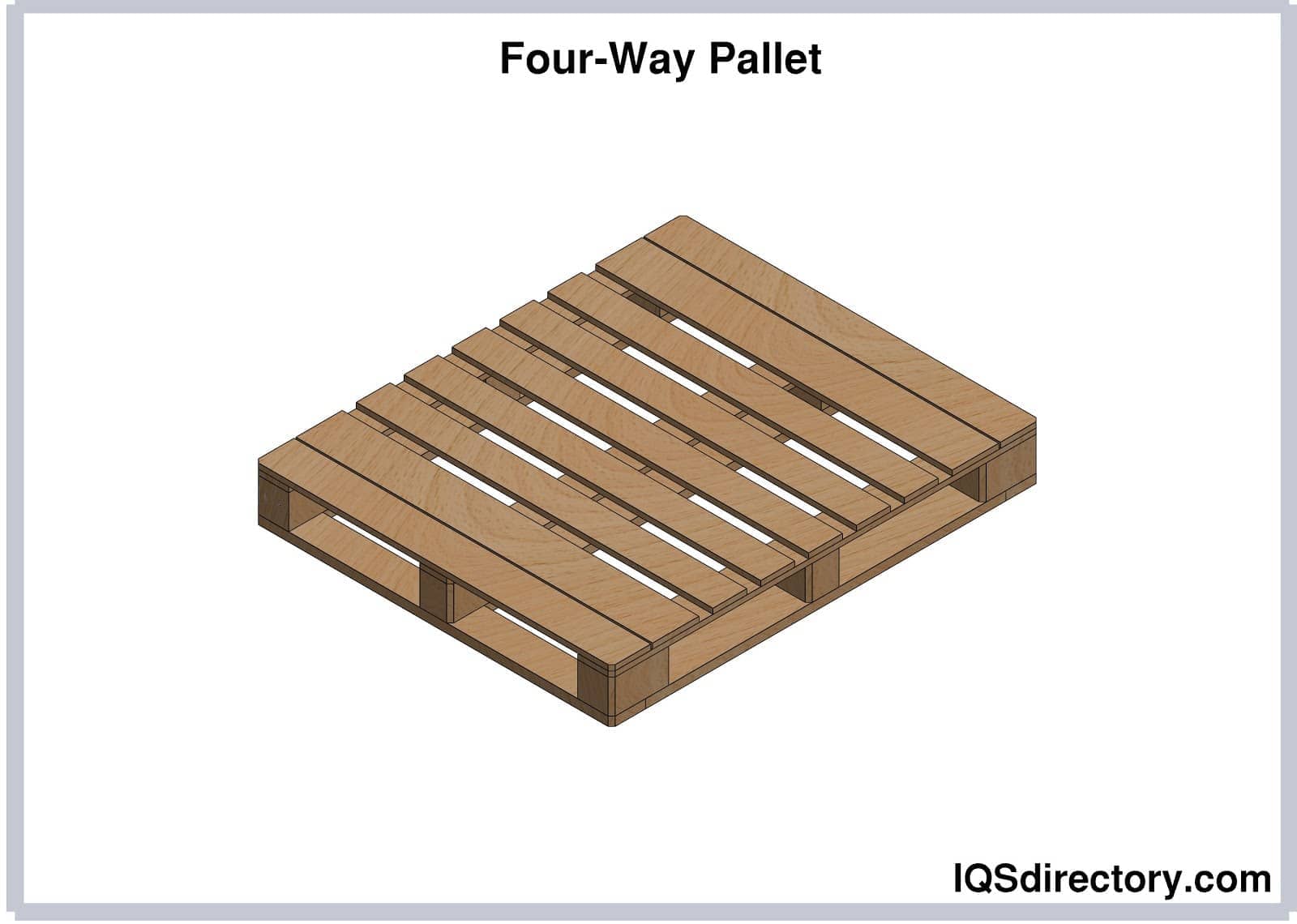

The reason for this bare construction is that rackable pallets are designed to fit squarely on those beams, which allows for their easy, safe and efficient placement and removal by forklifts and jacks. Read More…

TMF Corporation manufactures and supplies the Protech 4048 heavy duty plastic pallet. With inventory on hand, we have the ability quickly deliver and pallets we have in stock, including the FM approved Protech 4048 with color options, four-way entry and more.

At Premier Handling Solutions, we provide warehouse equipment solutions that improve overall productivity, safety and speed throughout the manufacturing, warehousing, distribution, consumption, storage and disposal process. Browse our selection of pallets, inverters, tippers, wire containers, and pallet dispensers to find the perfect product for your application.

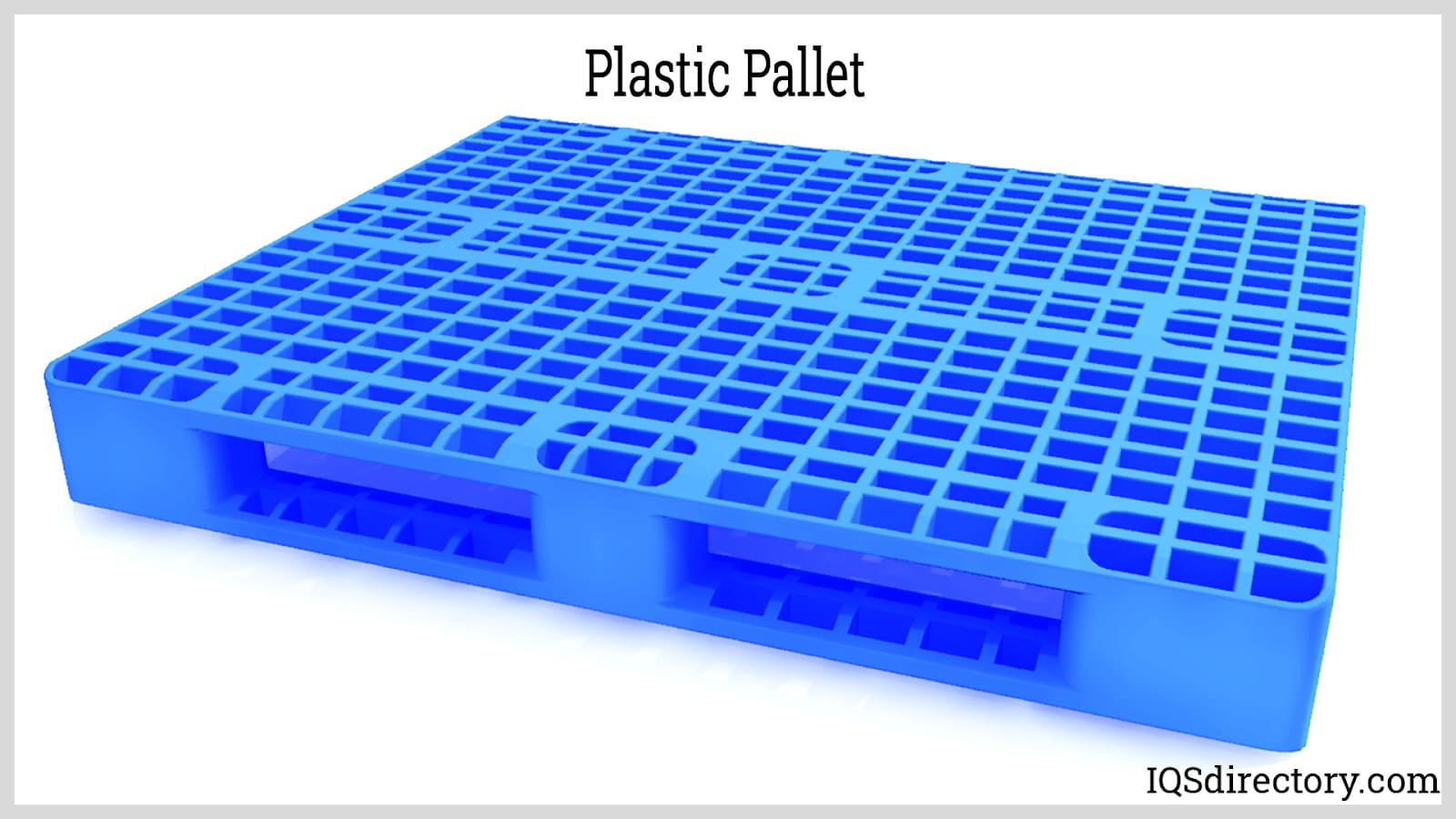

At Peninsula Plastics, you can find high-performance, vacuum-formed reusable plastic pallets for maximum strength and durability. Our economical twin-sheet & single-sheet pallets feature nestable and stackable models, large load capacity, many sizes, guaranteed acceptance at all ports, use in demanding applications, and with automated systems.

At Craemer US Corporation, we specialize in providing comprehensive solutions for plastic pallets tailored to meet the diverse needs of our clientele. With decades of experience and a commitment to excellence in the plastics industry, we have established ourselves as a trusted leader in plastic pallet manufacturing, renowned for our dedication to quality, innovation, and customer satisfaction....

Robinson Industries reduces operational costs and worker injuries through providing superior-quality plastic pallets. We sell pallets in a variety of sizes and styles. Robinson Industries is ready and able to meet diverse industry needs.

Fibertech Plastic pallets are an excellent alternative to wood pallets, offering cost-efficient solutions for strong, durable & washable pallets. Our unique angled leg design helps reduce forklift damage by enabling the fork tines to deflect off the leg rather than breaking or cutting the pallet. An optional lip prevents product slippage & facilitates transportation of stacked, empty pallets.

More Rackable Pallet Manufacturers

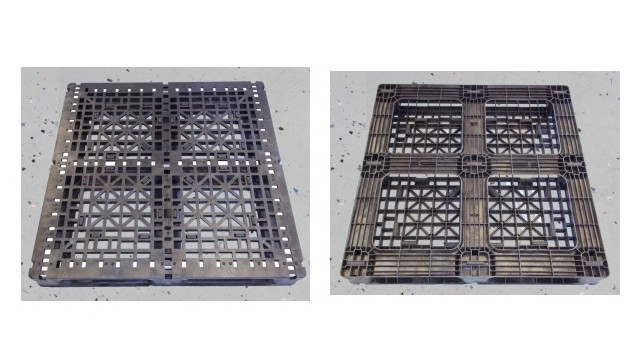

The base of a given rackable plastic pallet determines what kind of storage rack it is suited for. Many plastic pallet bases feature leg designs that allow for the easiest entry by forklift attachments. They usually feature four legs at the corners of the pallet frame, one leg in the middle of the pallet and one leg placed at the middle of each of the pallet's sides.

This construction allows for forklift access from any side, though forklift operators must be especially careful when racking this kind of pallet. Other varieties feature pallets with "picture frame" bases, which are completely flat on the top and bottom surfaces but feature hollow channels in their middles for forklift access.

Most rackable pallets are made of injection molded high-density polyethylene, or HDPE. HDPE is known for its strength and durability, which make it an excellent choice in demanding applications. The injection molding process is a common method for processing plastics because of its relative ease and simplicity.

The process requires a supply of raw plastic material; the material can be newly processed, or it can come from recycled plastic products. In both cases, the raw material is loaded into a conveyance channel that leads to a mold cavity. The mold cavity is specially designed in the shape of the intended plastic product.

A long screw in the conveyance channel heats and pressurizes the plastic material, which brings it to a molten state. The molten plastic is then ready to be injected into the mold cavity where it takes the mold's shape. Once it has been shaped, the plastic cools and hardens. It is then ejected from the mold and made ready for customer use.

Five other plastic fabrication processes are also used to create plastic pallets: structural foam molding, thermoforming, compression molding, rotational molding and profile extrusion. Injection molding is the most common process because it is a comparatively simple process and produces durable products.

55 Gallon Drums

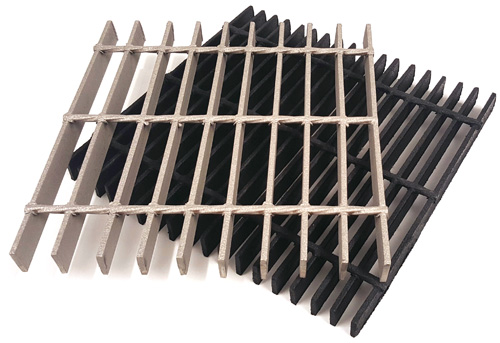

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Conveyors

Conveyors Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Lubricators

Lubricators Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches